Are you a mountain biking enthusiast who dreams of building your own bike from scratch? Meet Reto from Fribourg, Switzerland, who took that dream and made it a reality. After dabbling in creating everything from skis to kitchen knives, Reto embarked on his most ambitious project yet—designing and building his own custom carbon enduro bike, dubbed the Afterlife.

But how does one go from having an idea to crafting a fully functional, trail-ready bike? This article dives deep into Reto’s journey, the challenges he faced, and the design elements that make the Afterlife a one-of-a-kind ride.

From Dream to Reality: Crafting a Custom Carbon Bike

Building a mountain bike isn’t something that happens overnight—especially when you’re aiming for perfection. It took Reto over two years to finish the Afterlife frame, a process filled with trial and error. While Reto has a background in engineering and works in the composite industry, the complexities of building his own bike frame presented new challenges at every step. According to Reto, “I feel like I made every part of the frame at least three times before they turned out the way I wanted.”

Afterlife Details

Frame: FFC Afterlife

Shock: Rockshox Super Deluxe Ultimate, 160 mm

Fork: Rockshox ZEB Ultimate 29", 170 mm

Wheels: DT Swiss E 1900 / EX 1700

Tires: Schwalbe Magic Mary / Hans Dampf

Drivetrain: SRAM Eagle GX AXS

Brakes: Hope Tech 3 V4

Cockpit: Hope AM stem / Raceface Atlas handlebar

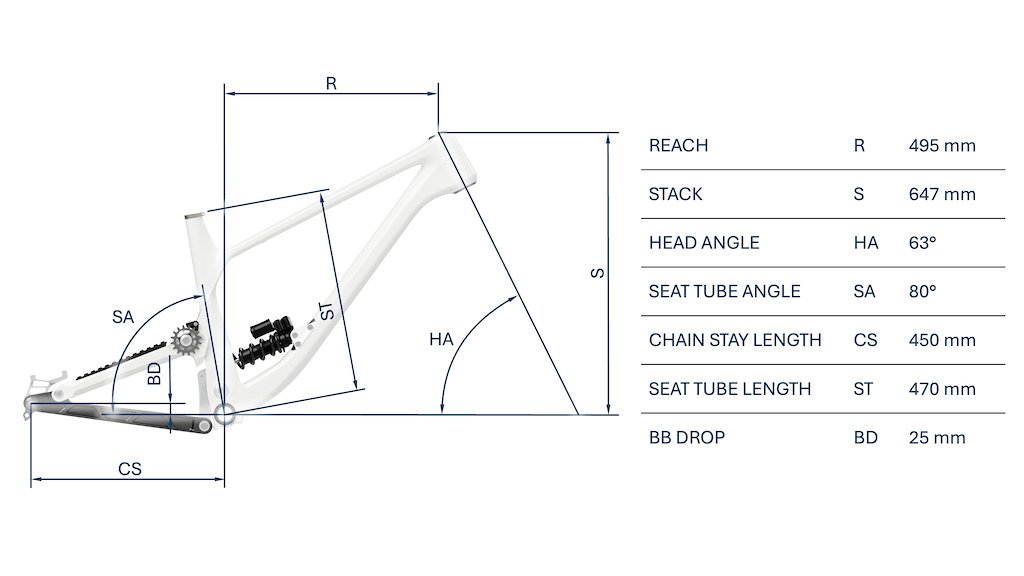

Size: Custom, 495 mm reach

Weight: 17.1 kg / 37.7 lb (as pictured)

More info: The Afterlife on the Custom Frame Forum

I called this frame Afterlife because after finishing this project, I finally have a life again.

Designing for the Ride You Love

When it comes to bike design, everyone has their preferences. Reto wanted a bike that was perfectly suited to the trails he loves: steep, rooty, gnarly, and rough. Rather than creating something poppy or agile, Reto built the Afterlife with one goal in mind—plowing through the toughest trails.

It’s not a bike built for cross-country riding, and Reto is the first to admit that it’s “hilariously bad” on XC trails. With a high pivot suspension design and 160mm of rear travel via a coil shock, this bike is all about traction and control in the most technical terrain.

The Geometry: Built for Gnarly Descents

When you’re building a bike for gnarly downhill sections, geometry plays a crucial role. The Afterlife features a steep 80° seat tube angle and a slack 63° head angle. These angles are perfect for Reto’s local trails, which are known for their challenging fire-road climbs followed by fast, technical descents. It’s the kind of geometry that’s designed for serious downhill performance, giving the rider a stable, controlled ride even on the gnarliest trails.

Reto took inspiration from other bikes on the market. When he started designing the Afterlife, the first generation of the Forbidden Druid had just been released, and its high-pivot design caught his eye. Reto incorporated similar principles into his own bike, combining them with his unique approach.

Suspension Design: An Engineering Feat

Building a suspension system from scratch is no easy feat, especially for a first-timer. Reto opted for a unique suspension layout—an upside-down Horst link, with the pivot located on the seat stay and a rocker link attached to the chainstay. The design also includes a shock tunnel where the shock is driven from the rocker link, a feature that made the entire project far more complex than Reto initially anticipated.

Interestingly, after he had completed the design of the Afterlife, Reto discovered that his suspension layout was similar to that of the Forbidden Dreadnought, a bike that was released after he finished his project. This reinforced Reto’s belief in his design choices.

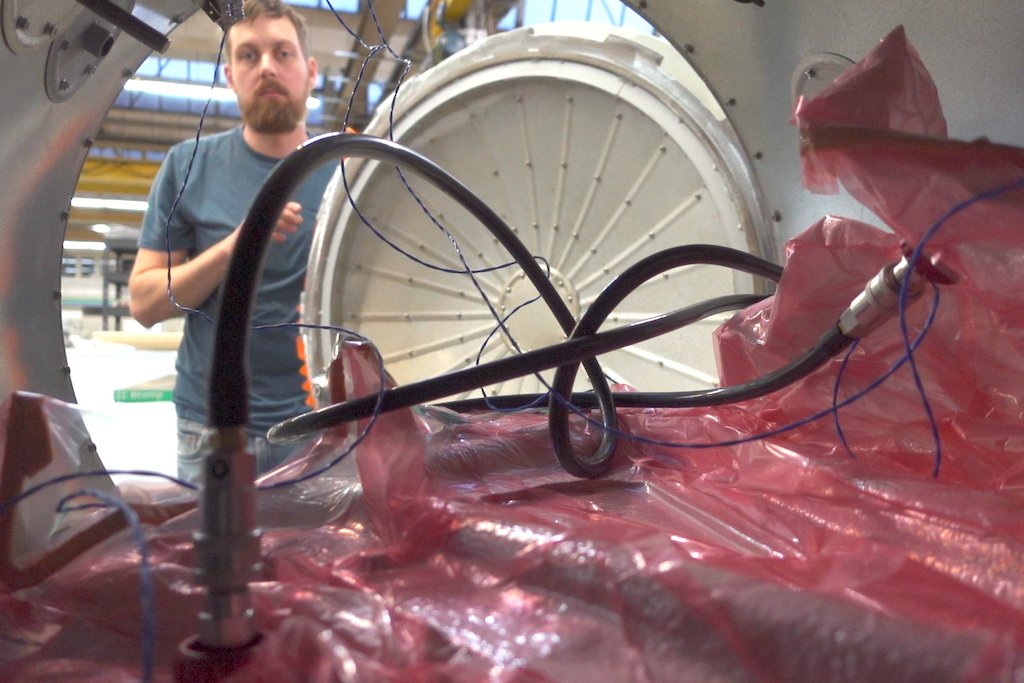

The Challenge of Building the Frame

The process of building the frame itself was fraught with difficulties. While Reto felt comfortable during the 3D modeling phase, translating those designs into a physical product was a different story. Laminating the front triangle of the frame proved especially challenging, taking him about 35 hours and requiring multiple attempts. In fact, the first two laminations were unsuccessful, forcing Reto to redo the process from scratch.

To optimize the carbon layup, Reto turned to reverse engineering. He cut up an old bike frame, burned away the resin with a blow torch, and meticulously studied the layers of carbon fiber. This process allowed him to analyze the surface weight and fiber orientation, helping him fine-tune the construction of the Afterlife.

Finishing Touches: The Struggles of Painting and Refining

Once the frame was finally built, Reto faced another challenge—painting. While he initially thought the painting process would be straightforward, achieving a factory-level finish was much more difficult than he had anticipated. It was yet another learning curve, but one that Reto tackled with the same persistence he had applied to the rest of the project.

What’s Next for the Afterlife?

While Reto is proud of the finished product, he’s not ready to start mass-producing Afterlife frames anytime soon. The time, effort, and cost involved in testing the frame and offering multiple sizes would be substantial. For now, the Afterlife remains a one-of-a-kind bike, tailored to Reto’s preferences and riding style.

That said, Reto isn’t done tinkering. He’s considering a few upgrades for the future, such as reworking the rear triangle to improve heel clearance and integrating a lower idler pulley for better shifting performance. He’s even thinking about experimenting with a floating brake mount, just to see how it affects the bike’s overall performance.

Building Your Own Bike: Is It Worth It?

Reto’s story is one of passion, dedication, and a willingness to step outside of his comfort zone. While building your own bike may seem like a daunting task, it’s also an incredibly rewarding experience for those who are willing to put in the time and effort.

If you’re considering building your own custom bike, take a page from Reto’s book: be prepared for challenges, setbacks, and a steep learning curve. But if you stick with it, you might just end up with a bike that’s not only unique but perfectly suited to your riding style.

MTBSA Conclusion: The Afterlife – A Testament to DIY Passion

The Afterlife is more than just a mountain bike—it’s a testament to the power of DIY passion and the pursuit of perfection. Built from the ground up by a rider who knew exactly what he wanted, it’s a bike designed for the toughest trails and the most technical descents.

Whether or not you’re considering building your own bike, Reto’s journey is an inspiring reminder that with enough dedication, patience, and a willingness to learn, you can turn even the most ambitious dreams into reality. So, the next time you hit the trails, take a moment to appreciate the craftsmanship and engineering that goes into the bikes we ride—and maybe even dream of building one yourself.

Photography by Reto Aebischer & TEBP

It’s perfect time to makke some plans for the longer term

and it is ttime too be happy. I’ve read this post and if I may I want too counsel you some

attention-grabbing things or tips. Maybbe yoou can write subsequen articles

regarding tis article. I wish to learn even more issues about it!

Feel free to visit my webpage – https://www.mediaskat.com.ua/